Faire du ballon de sport

un objet engagé

porteur de valeurs fortes

L’entre-aide, la solidarité, le dépassement de soi… tant de valeurs portées par le domaine du sport, et à travers lesquelles notre société aime prendre exemple et s’inspirer. Les sports populaires d’aujourd’hui sont des vitrines incontournables et ont cette force de pouvoir véhiculer des messages forts. Nous sommes déterminés à faire du sport le vecteur de nouvelles valeurs environnementales, à travers un porte-parole emblématique, objet central sur un terrain de sport : le ballon.

Le ballon peut dire beaucoup de choses sur la société dans laquelle on vit ; le ballon est partout, populaire et fédérateur. Mauvais élève en matière de RSE, en agissant sur son marché, nous souhaitons faire prendre au ballon l’indispensable tournant écologique, et en faire un véritable catalyseur auprès des acteurs du milieu sportif.

Le ballon est

un langage

universel.

On aime jouer

avec lui et le passer à un ami,

un inconnu.

Acteur principal sur un terrain de jeu, nous avons élu le ballon de sport comme porte-parole emblématique.

Celui d’un monde qui change et rebondit vers un futur harmonieux, respectueux de l’homme et de son environnement.

Chez Rebond, nous souhaitons réaliser des ballons de sport autrement : grâce à nos innovations, nous avons choisi d’en faire un produit éthique, éco-responsable et local.

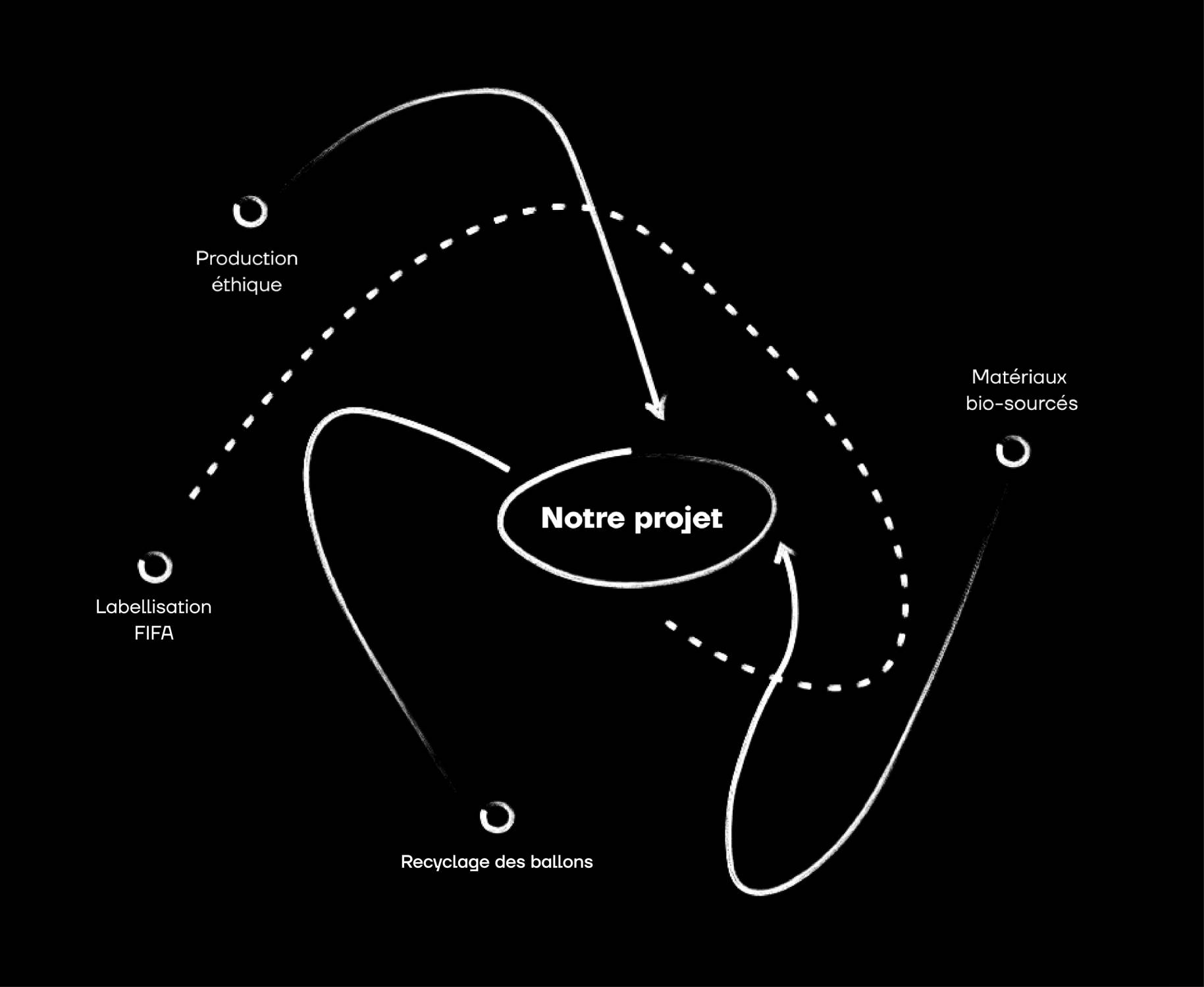

Pour se faire, nous travaillons sur trois axes principaux :

-Développer des ballons en matériaux bio-sourcés (= avec des résidus de matières organiques)

-Mettre en place une économie circulaire autour du ballon en recyclant ou upcyclant les produits en fin de vie

-Développer une chaîne de production française

Des ballons

en matériaux

bio-sourcés

et recyclables

Créer une vraie économie circulaire autour du ballon : tel est notre leitmotiv.

Grâce à notre R&D, on peut aujourd’hui l’affirmer : réaliser des ballons recyclables et dont les matériaux proviennent de résidus organiques, c’est possible !

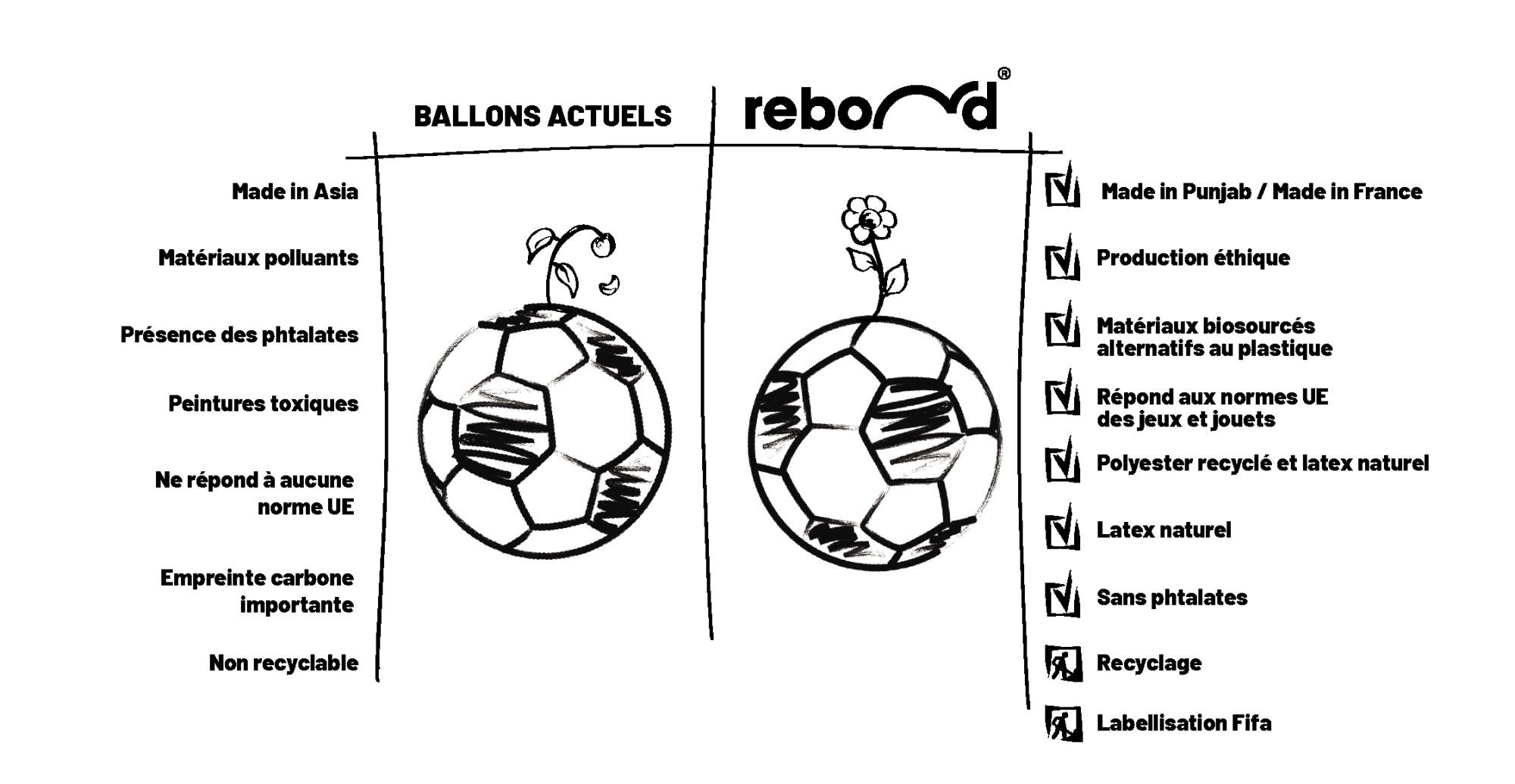

En réinventant la manière de réaliser du ballon de sport, nous avons ainsi réduit la part d’énergie fossile dans le ballon, pour travailler avec un maximum de matériaux naturels. En rendant le ballon mono-matière, nous l’avons rendu recyclable. Accompagnés par des industriels français qui ont rejoint l’aventure, nous avons enfin pu sortir le premier ballon bio-sourcé, recyclable, répondant aux normes internationales de compétition, en 2022.

À l’intérieur du ballon, nous utilisons du polyester recyclé et une chambre à air en latex naturel, afin d’avoir le ballon le plus sain possible.

Aujourd’hui, nous sommes capables de créer des ballons « cleanés » au maximum, ne contenant aucun phtalate, et dont les encres utilisées répondent aux normes strictes européennes du jeu et du jouet (EN71).

Nous continuons de travailler à réduire encore et encore l’impact de la production de ballons sur notre environnement et souhaitons proposer une gamme Technique premium, labellisée et logotée par les instances internationales telles la FIFA pour le football, afin proposer nos ballons aux clubs de sport.

La production des ballons actuels : Le saviez-vous?

Vous entendez parler de simili cuir lorsque l’on vous parle de ballon de football ? Derrière ce terme se cache « simplement » celui de plastique : tous les ballons de jeu sont aujourd’hui réalisés en PVC ou PU.

À l’heure où nous tendons tous vers un monde plus sain, et une consommation engagée autour de produits respectueux de l’homme et de son environnement, le ballon fait office de mauvais élève à travers ses matériaux utilisés et dans ses modes de production.

D’autant qu’aucune norme européenne ne régit le ballon de sport à l’entrée sur notre territoire : une porte ouverte à beaucoup de dérives.

Derrière notre ambition, se cache un vrai enjeu sociétal : celui d’influer un impact positif en produisant autour de matériaux sains pour respecter l’homme en tant qu’utilisateur et producteur, ainsi que notre planète.

Nous avons l’envie forte de montrer que nous pouvons faire pivoter une économie existante en la basant sur un socle de valeurs écologiques et sociaux inamovible.

Made

in France

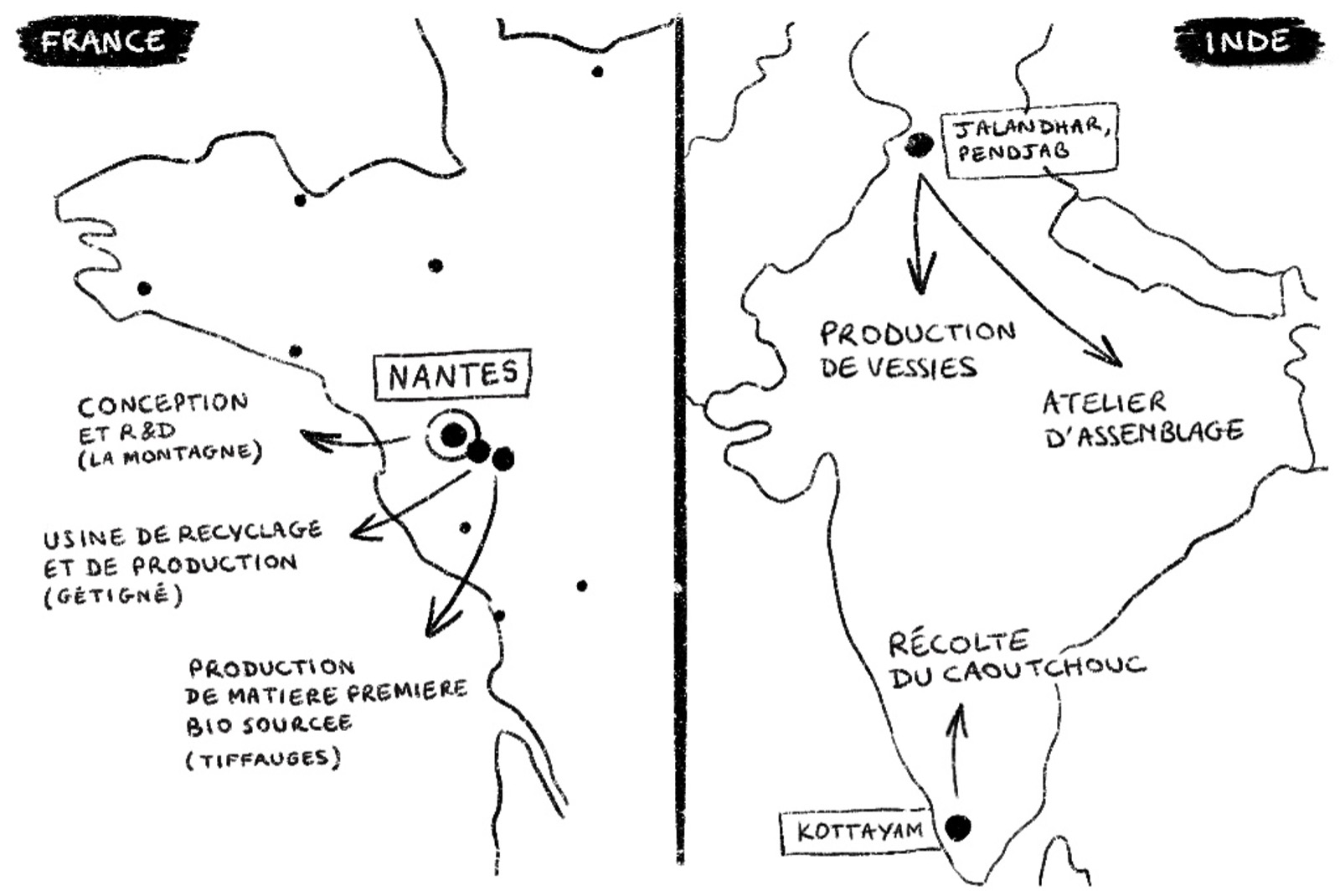

Travailler avec Le Pendjab, berceau historique du ballon de sport, et créer une chaîne de production en France : un beau challenge !

De nos jours le Pendjab (région à cheval entre le Pakistan et l’Inde) réalise 85% de la production mondiale manuelle de ballons de sport. Un savoir-faire culturel que les deux pays ont acquis à travers leur histoire, et qui fait partie de leur héritage. Le ballon est à cette région du monde ce qu’est le savon à Marseille, le marbre à l’Italie, le cachemire à l’Inde.

Forts de la connaissance de cette histoire au Pendjab qui a vu naître un reportage vidéo sur l’histoire du ballon , notre envie n’est pas de délocaliser un savoir-faire pendjabi, développant l’économie locale. Notre souhait est de développer une chaîne de production française complémentaire à ces ateliers. Nous avons la chance en France d’avoir accès à une ingénierie d’excellence, nous permettant de challenger les matériaux utilisés sur le ballon. Nous voyons ainsi ces savoirs français et pendjabi complémentaires. L’éco-responsabilité devant être vue à notre sens de manière internationale et non nationale.

Depuis 2019, nous avons développé une chaîne de production française dont l’atelier d’assemblage se trouve en Loire-Atlantique (44).

Entreprise française

Paiement sécurisé

Ballons livrés gonflés sous 3 à 5 jours ouvrés

Service client