Transparence

Les questions essentielles

L’industrie du ballon fait face à de nombreux défis. Chez Rebond, nous nous sommes posé les questions indissociables aux challenges écologiques, humains et économiques induits par cette filière de production.

Comment sont fabriqués les ballons ? Où sont-ils assemblés ? Quels matériaux sont utilisés ? Comment sont rémunérés nos collaborateurs ?

Pour répondre à ces questions, nous nous sommes d’abord intéressés au ballon le plus populaire de sa génération : le ballon de football. Voici nos réponses à ces problématiques essentielles, qui font la raison d’être de Rebond.

Enveloppe, matières, composants...

Sous ses 32 panneaux assemblés à la main ou en machine, le ballon de foot classique cache plusieurs couches de matières : feuille de PVC ou de PU, mousse en EVA ou en PU, entoilage en polyester ou en coton, vessie en latex, PVC ou résine, encres.

- L’ENVELOPPE EXTERNE

L’enveloppe externe du ballon de foot est composée de 3 couches de matières différentes essentielles pour en faire un objet performant sur le terrain. Ces différents matériaux fermant la porte à la recyclabilité, le ballon est un produit qui fini incinéré une fois en fin de vie. Aujourd’hui, en France, et juste sur le football, plus d’un million et demie de ballons sont jetés chaque année. Chez Rebond, des mois de R&D ont été nécessaires pour arriver à un assemblage complexe en éco-conception, qui soit mono-matière et capable d’atteindre les mêmes qualités techniques que le ballon de compétition. Le mono-matière ouvrant la prote de la recyclabilité du produit.

Principale innovation de Rebond : le bio-sourcé. Ce que nous appelons matériaux bio-sourcés sont des matériaux issus non plus d’énergie fossile mais majoritairement d’énergie provenant de résidus de matières organiques, végétales. Chez Rebond, ce complexe de matières végétales est réalisé à partir d’huile de soja récolté en Ukraine et transformé en France, dans notre région de Loire-Atlantique.

Au-delà de sa composition bio-sourcée , ce nouveau matériau nous permet la production d’une enveloppe mono-matière qui permet le recyclage du ballon, jusqu’à présent impossible.

La feuille externe

Cette fine couche de matière souple et résistante est la partie visible du ballon, sur laquelle nous imprimons nos designs. Chez Rebond, cette enveloppe est réalisée en PVC ou PU bio-sourcé, issu au minimum de 51% de matières organiques renouvelables.

> Rapport d’analyse sur les matériaux bio sourcés

La Mousse

Également conçue à partir du PVC ou PU bio-sourcé issue de notre R&D, la mousse est l’élément indispensable qui assure l’amorti du ballon. Elle ne fait qu’un avec la feuille externe, ce qui nous permet le recyclage des matières.

L’entoilage

Cette couche est fabriquée soit en RPET, c’est-à-dire en polyester recyclé, soit de la même base de matière que l’enveloppe. Elle vient renforcer l’assemblage des matières et faciliter le montage du ballon. L’entoilage est collé à la couche de mousse avec du latex naturel, pour lui donner du rebond. En cas d’utilisation de RPET 10 bouteilles en plastiques recyclées sont nécessaire pour créer la feuille d’entoilage d’un ballon.

> Rapport d’analyse sur le polyester recyclé

LA VESSIE

Dernier élément d’assemblage, la vessie permet de gonfler le ballon. Elle donne à l’enveloppe externe sa forme parfaitement ronde.

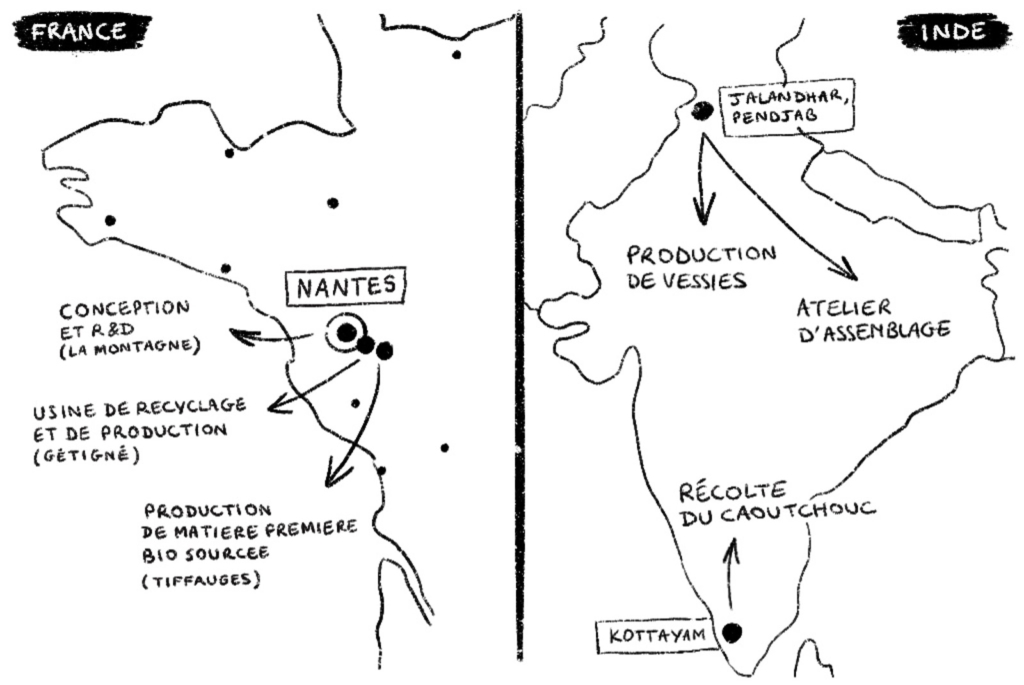

Nos vessies sont réalisées en caoutchouc naturel récolté au sud de l’Inde, puis produites à Jalandhar, à quelques pas de notre atelier d’assemblage. Le caoutchouc naturel est une substance élastique qui provient du latex, soit de la transformation de la sève de végétaux. Les forêts dans lesquelles nous nous approvisionnons sont gérées par l’état de façon durable sous le label international PEFC.

LES ENCRES

Aujourd’hui, il n’existe aucune règlementation concernant les encres et peintures utilisées sur les ballons vendus en France.

Chez Rebond, nous avons donné un cadre au ballon en appliquant les normes européennes du jeu et du jouet avec l’utilisation d’encres EN71, ou encres végétales, qui permettent l’utilisation du produit par un enfant et sont exemptes de dangers en termes de toxicité, de migration et d’inflammabilité.

Conception, approvisionnement, production…

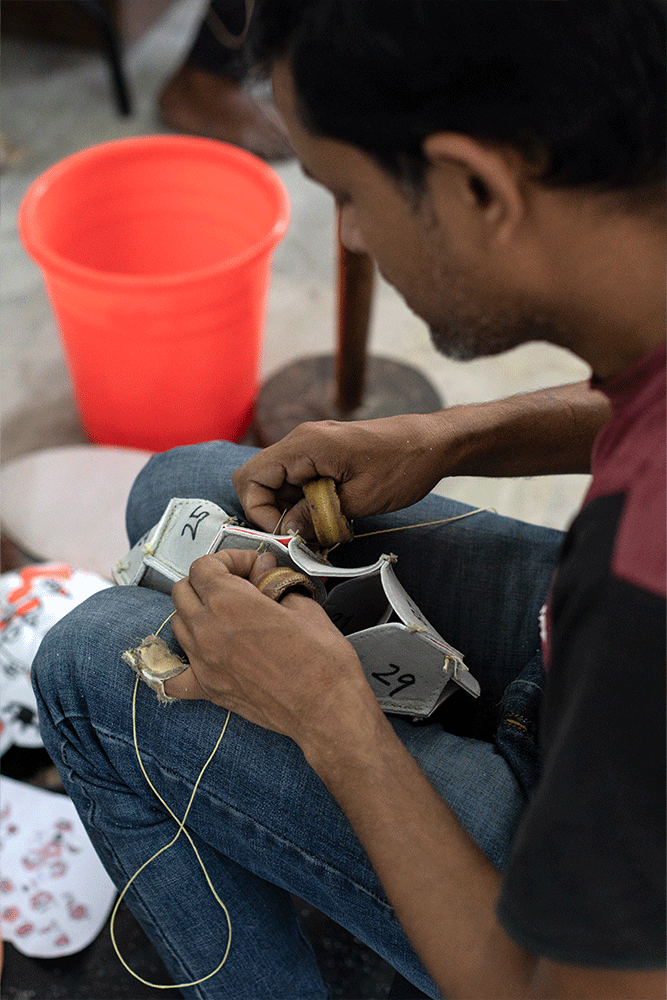

À cheval entre l’Inde et le Pakistan, le Pendjab est la région qui a vu naitre le ballon dans les années 30, lors de la période coloniale. Bien que la Chine ait récupéré une partie du marché lors de son développement industriel récent, 85% de la production manuelle de ballon reste originaire du Pendjab, du fait de son savoir-faire historique.

Pour continuer à valoriser le savoir-faire local, nous avons choisi de renforcer les liens avec les producteurs Pendjabi. Nous contribuons au développement économique de cette région spécialiste en travaillant sous la norme Fairtrade, qui nous permet de rémunérer justement et en toute transparence avec nos partenaires.

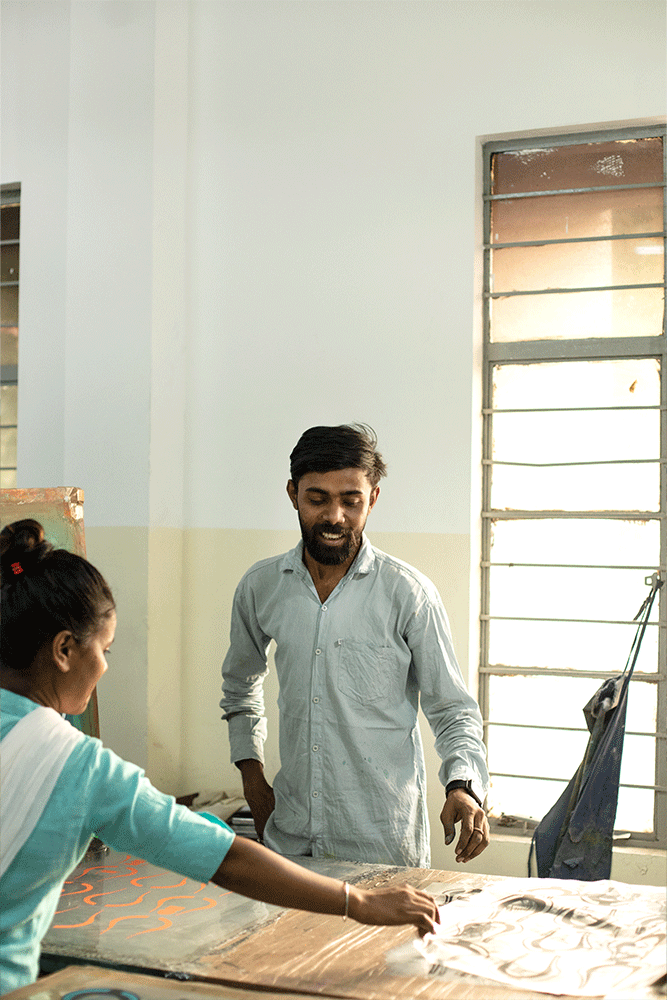

Aujourd’hui, Anurag et Anuj – père et fils directeurs d’atelier d’assemblage Pundjabi – font partie intégrante du projet Rebond. Experts du ballon, ils interviennent en tant que véritables guides et partenaires dans notre conduite de R&D. Notre but est aussi d’impulser une conscience RSE dans cette région du monde.

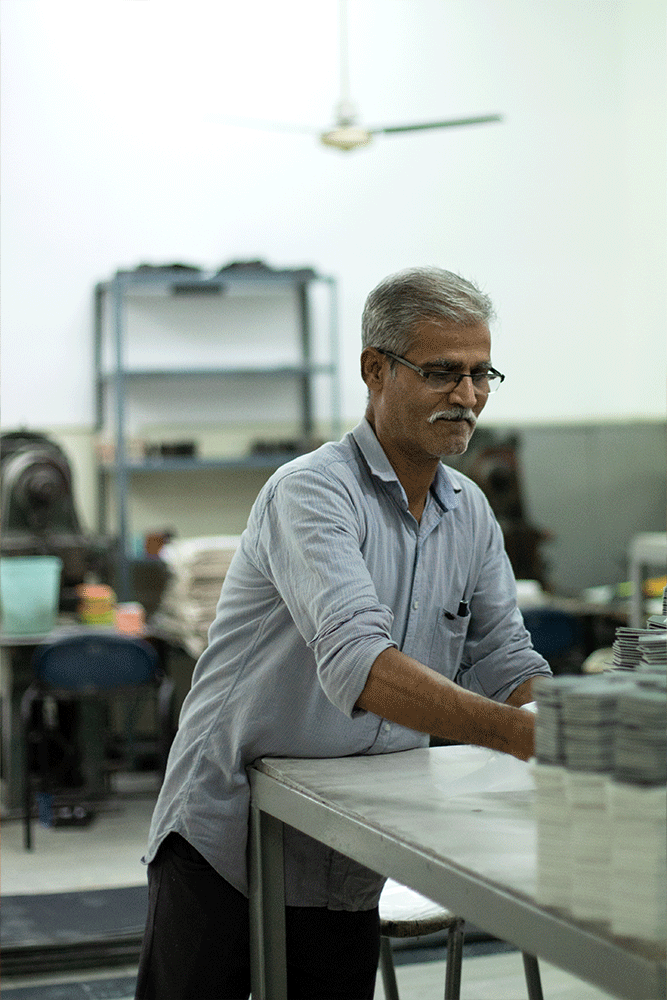

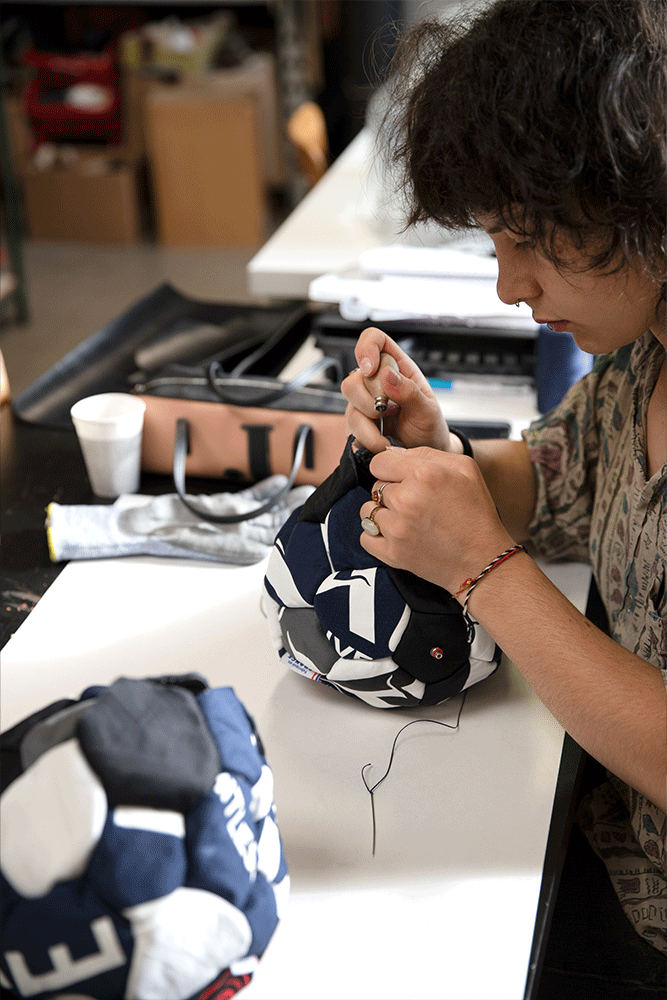

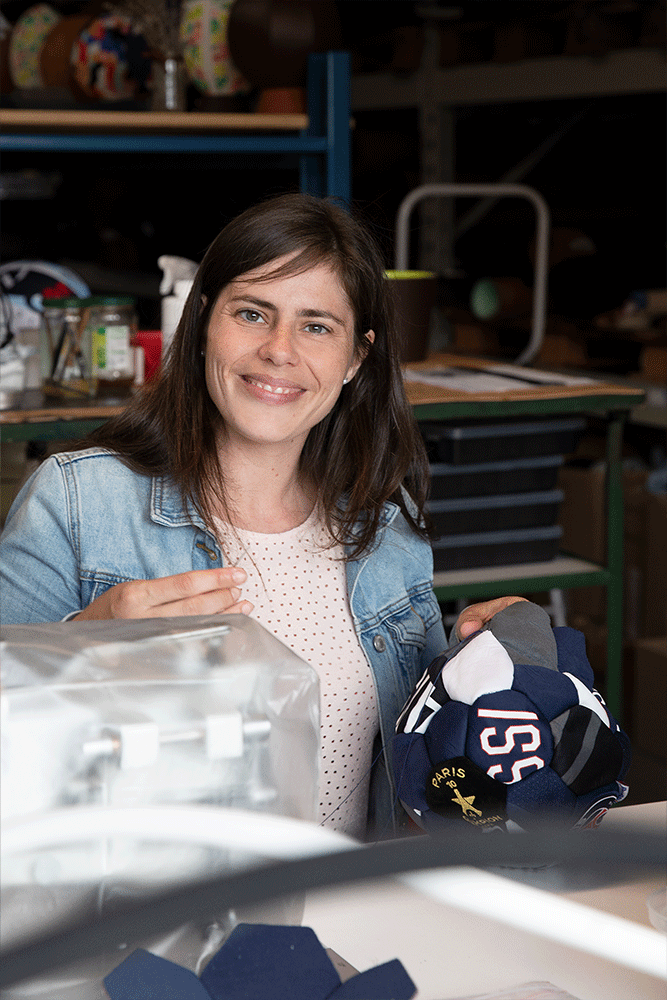

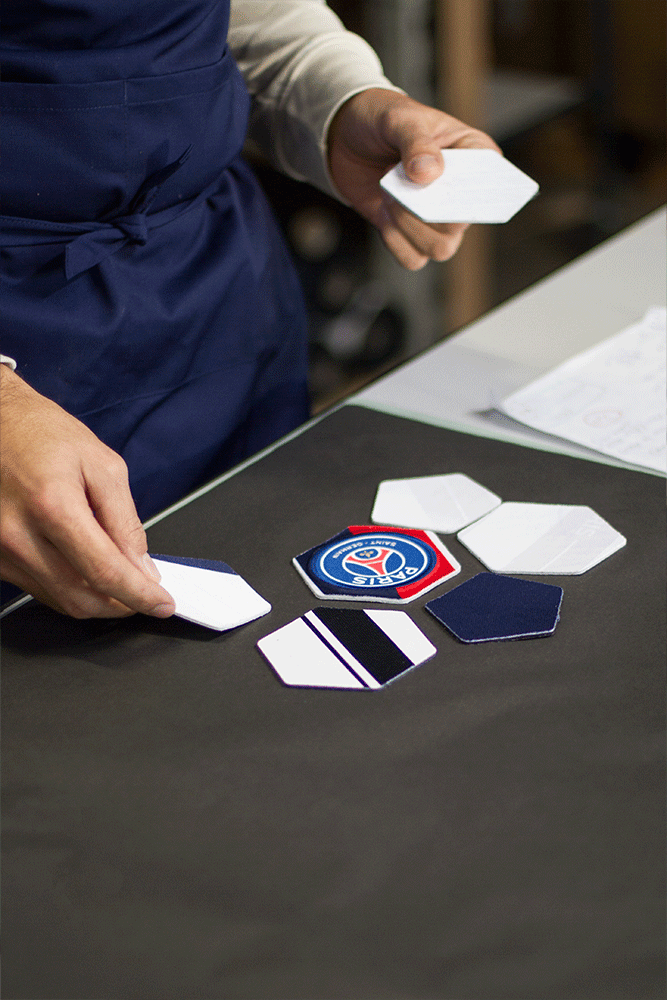

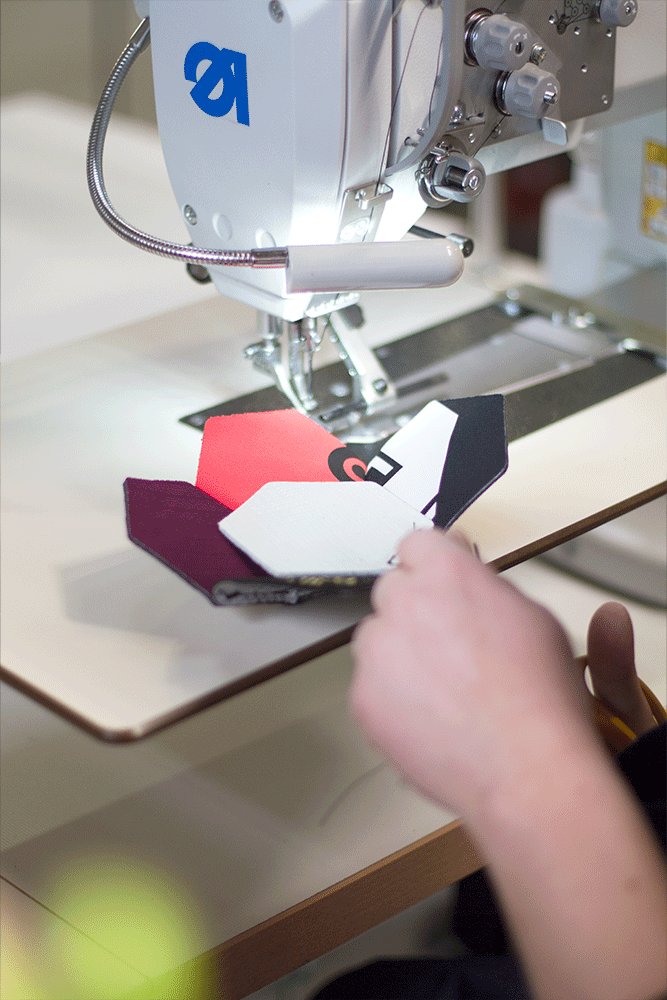

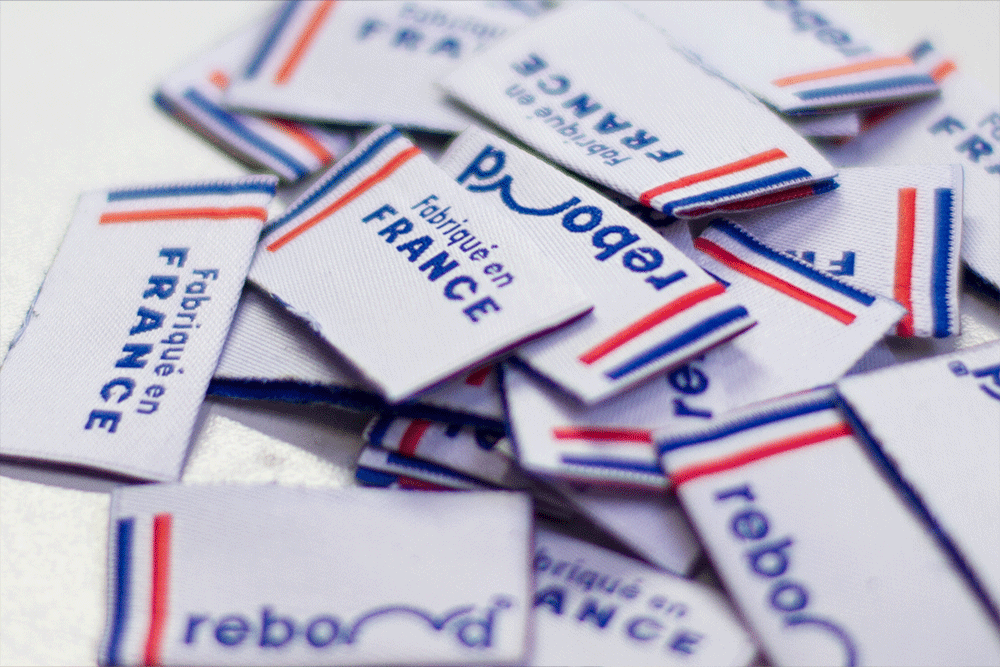

En parallèle de notre atelier Pendjabi, nous travaillons avec un site de production français, situé à quelques kilomètres de Nantes. Initialement spécialistes du cuir et de la chaussure, ils ont su apprivoiser le produit complexe qu’est le ballon, car il suit les mêmes étapes de production.

Grâce à Thomas, chef de production, nous avons développé ensemble un atelier d’assemblage spécifique au ballon au sein de leur usine. Ballon maillot, ballon en cuir, ballon de jeu… L’accès à nos innovations lié au savoir-faire haut de gamme de la couture Française nous a permis de réintroduire le ballon Made in France, avec des projets en collaboration avec le Paris Saint-Germain, le Bayern de de Munich, la FFF… Et d’autres à venir !

Maitrise technique et haute-couture

Rebond fait le choix de travailler en France et au Pendjab, pour lier deux cultures aux savoir-faire historiques complémentaires. Le Pendjab, c’est la maitrise du ballon sous toutes ses coutures. La France, c’est la haute-couture qui profite d’un accès privilégié à des ressources de R&D.

Le ballon Made in France n’existerait pas sans le Pendjab, et le ballon éco-conçu n’existerai pas sans la France : nous travaillons main dans la main pour se tirer chacun vers le haut.

Fairtrade, 1% For The Planet, associations…

Parler écologie, c’est aussi parler Humain. Les relations que nous entretenons avec nos partenaires sont primordiales et occupent une grande place lors de la prise de décisions au sein de Rebond. Fournisseurs, producteurs, associations… Nous traitons chaque collaborateur avec beaucoup de respect et de considération pour leur travail.

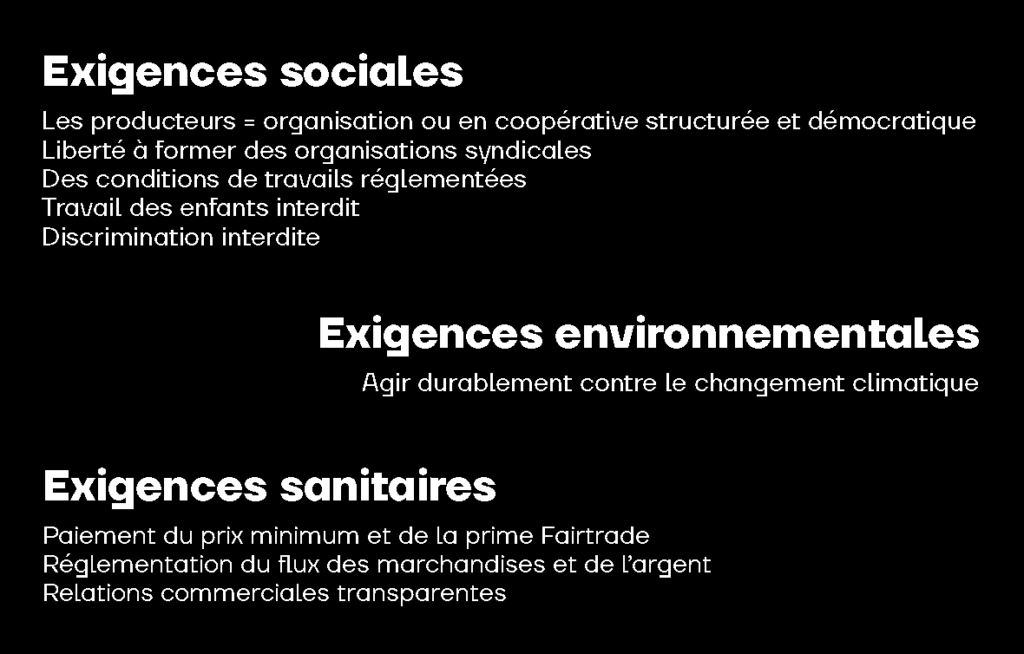

Fairtrade

Rebond travaille avec tous ses partenaires sous le principe du commerce équitable. Nos engagements commerciaux sont fondés sur le dialogue, la transparence, et le respect dans le but d’atteindre une plus grande équité dans nos échanges marchands.

Dans ce but, les ballons Rebond sont produits sous la norme Fairtrade de l’ONG Max Havelaar. La norme Fairtrade permet d’assurer aux producteurs un prix juste et stable, des relations commerciales durables et la mise en place de mesures pour la protection de l’environnement et la sécurité des employés.

Par cet engagement, nous reversons également la Prime Fairtrade aux travailleurs, qui leur assure un revenu décent, supérieur au salaire moyen local.

> Lire le détail de notre engagement Fairtrade

1% For The Planet

Au-delà du ballon, nous souhaitons nous engager durablement. Pour cela, nous sommes liés au collectif mondial 1% For The Planet à qui nous reversons 1% de notre chiffre d’affaire annuel pour qu’il soit redistribué à des associations, organisations et entreprises œuvrant pour la préservation de l’environnement.

Aujourd’hui, 1% For The Planet c’est déjà 6000 membres dans près de 91 pays, et plus de 350 millions de dollards consacrés à des associations environnementales.

Engagement associatif

Derrière chaque projet, nous souhaitons mettre en lumière et soutenir une association.

L’accès au logement aux cotés de la fondation Abbé Pierre, le soutien aux soignants avec la Fondation des Hôpitaux de Paris ou encore le cancer pédiatrique avec Run For Hope… Nous vendons nos ballons aux profits de diverses causes en travaillant avec des artistes, des marques, et des entreprises engagées.

Nos limites, nos espoirs, nos projets

Un ballon issu de matières végétales, ça n’avait encore jamais existé.

Mais comment est cultivé le soja ? Quelle est la part de bio-sourcé dans le produit fini ? Notre engagement Fairtrade est-il suffisant ?

De nombreuses questions restent en suspens. Parce que le ballon végétal, ce n’est pas que ça. C’est aussi notre engagement durable et notre volonté de rester transparent vis-à-vis du produit. Conscient des défis à relever dans dans les années à venir, voici les questionnements qui tracent la route vers le ballon de demain.

Surface externe : En travaillant avec des matériaux bio-sourcés, nous réduisons notre impact sur la planète en économisant les ressources en énergies fossiles. Mais le bio-sourcé connaît des limites et un produit ne peut à ce jour être 100% bio-sourcé. Dans notre cas, il l’est à 51%. Ce qui est certes une grosse avancée, car 51% d’énergie fossile est « économisée » avec notre ballon. Mais nous devons chercher à aller encore plus loin, nous entamons déjà des tests afin d’atteindre plus de 80% de bio-sourcé sur notre surface externe.

Et peut-être que la solution se trouvera ailleurs que dans le bio-sourcé, cette marche franchie nous emmènera vers de nouveaux horizons, c’est certain.

Surface interne : L’entoilage de nos ballons est fait en polyester recyclé, issu de bouteilles plastiques. C’est la couche qui nous empêche d’avoir un produit 100% mono-matière à ce jour, et qui nous impose une séparation des matières lorsque nous souhaitons recycler le ballon. Nous travaillons actuellement à uniformiser à 100% les matières utilisées sur nos ballons afin de favoriser le recyclage de nos produits.

La vessie : C’est un produit sur lequel nous n’avons pas axé notre R&D. Nous travaillons avec des matières d’origines naturelles (caoutchouc, latex) issues de plantations responsables gérées par le gouvernement indien. Il nous faut encore aller plus loin sur cet axe, en cherchant à labelliser l’environnement social des producteurs via notre partenaire Fairtrade par exemple. Nous travaillons déjà le recyclage de ces matériaux mais ne l’avons pas internalisé, ce qui a un impact en terme de transport.

Enfin, il y a un point de vigilance autour du travail de ces matières par vulcanisation ; il nous faut nous assurer du respect de seuils limites d’émissions.

Le coton : Dans le ballon, il y a du coton. Il est utilisé pour les fils de couture servant à assembler le ballon. C’est certes un emploi minime par rapport aux autres matériaux, mais la culture du coton nécessite un apport en eau important, et est souvent issue de cultures intensives utilisant de la mécanisation. Il nous faut entamer des démarches afin d’accompagner nos fournisseurs vers une labellisation (ex : GOTS) ou même envisager d’autres fibres textiles moins à risques comme le lin ou le chanvre.

Quelques autres enjeux à adresser ou à surveiller : Nous devons avoir un œil attentif au transport tout long du cycle de vie de nos produits, ainsi qu’à la maîtrise de la fin de vie du produit, en proposant un système de récupération des ballons usagés qui soit simple et efficace.

Nous devons être à l’écoute en général, et à votre écoute en particulier ; nous nous sommes faits accompagnés par une entreprise externe pour analyser le cycle de vie de nos produits : EVEA, et essayons de travailler tous les jours avec bon sens, pour vous proposer un produit qui fait sens.

L’échange de savoirs, de connaissances, et de sensibilités sont pour nous les clés d’un produit bien conçu. Car nous en sommes convaincus, la réponse au défi actuel de notre société sera collective.

Entreprise française

Paiement sécurisé

Ballons livrés gonflés sous 3 à 5 jours ouvrés

Service client