Make the

sports ball a committed object

conveying strong values

Helping each other, solidarity, surpassing oneself... so many values carried by the field of sport, and through which our society likes to take example and be inspired. Today's popular sports are essential showcases and have the strength to convey strong messages. We are determined to make sport the vector of new environmental values, through an emblematic spokesperson, a central object on a sports field: the ball.

The ball can say a lot about the society in which we live; it's everywhere, popular and unifying. A bad pupil when it comes to CSR, by acting on its market, we hope to make the ball take the indispensable ecological turn, and turn it into a real catalyst for players in the sporting world.

The ball is

a universal language

.

We like to play

with it and pass it on to a friend,

a stranger.

As the main player on a playground, we have chosen the sports ball as our emblematic spokesperson.

A world that is changing and bouncing towards a harmonious future, respectful of mankind and the environment.

At Rebond, we want to make sports balls differently: thanks to our innovations, we have chosen to make them an ethical, eco-responsible and local product.

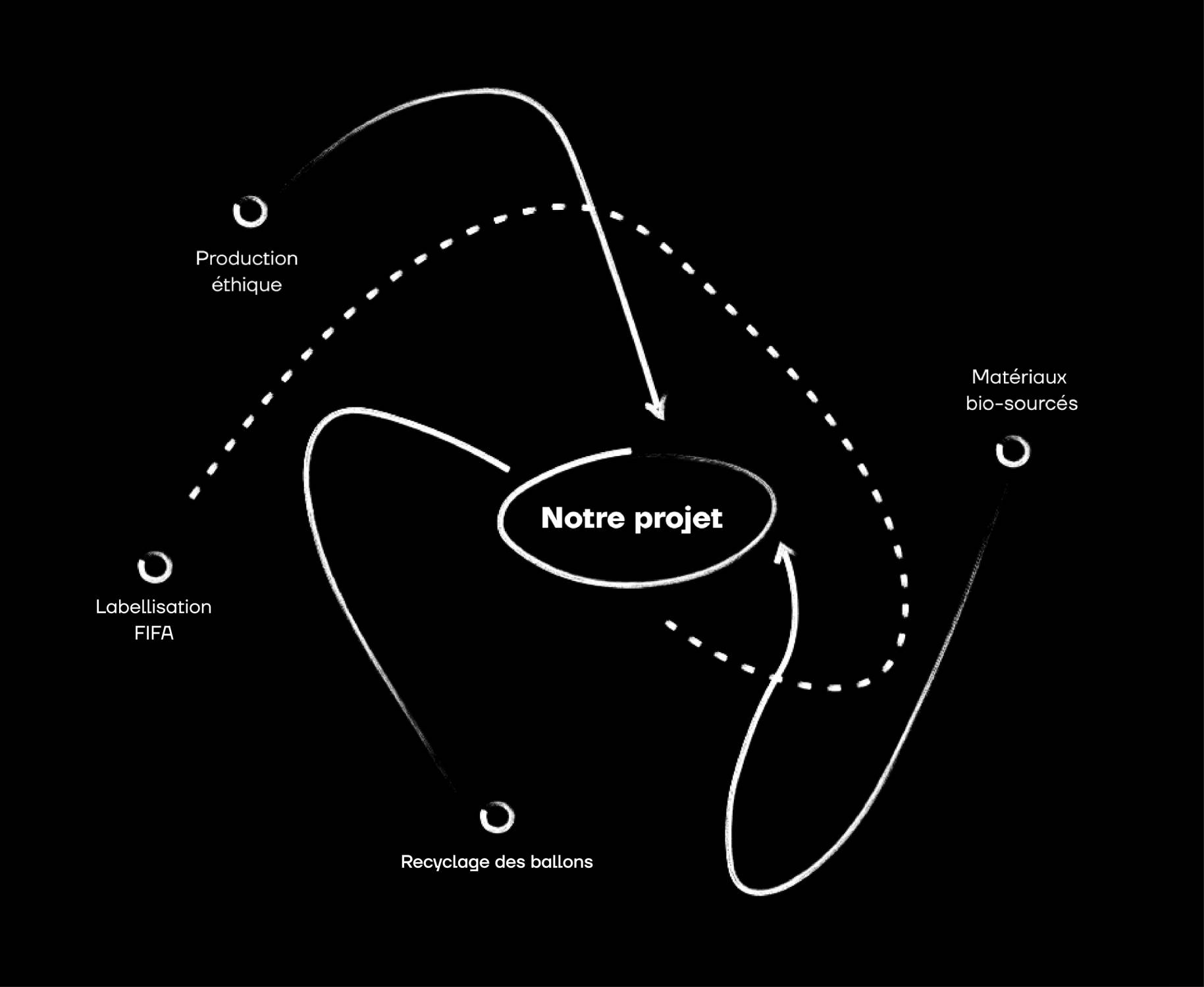

To do so, we are working on three main axes :

-Develop balls in bio-sourced materials (= with organic material residues)

Set up a circular economy around the balloon by recycling or upcycling end-of-life products

-Develop a French production chain

balloons made from

bio-sourced materials

and recyclable

Creating a true circular economy around the ball: that's our leitmotiv.

Thanks to our R&D, it's now possible to make balloons that can be recycled and whose materials come from organic residues!

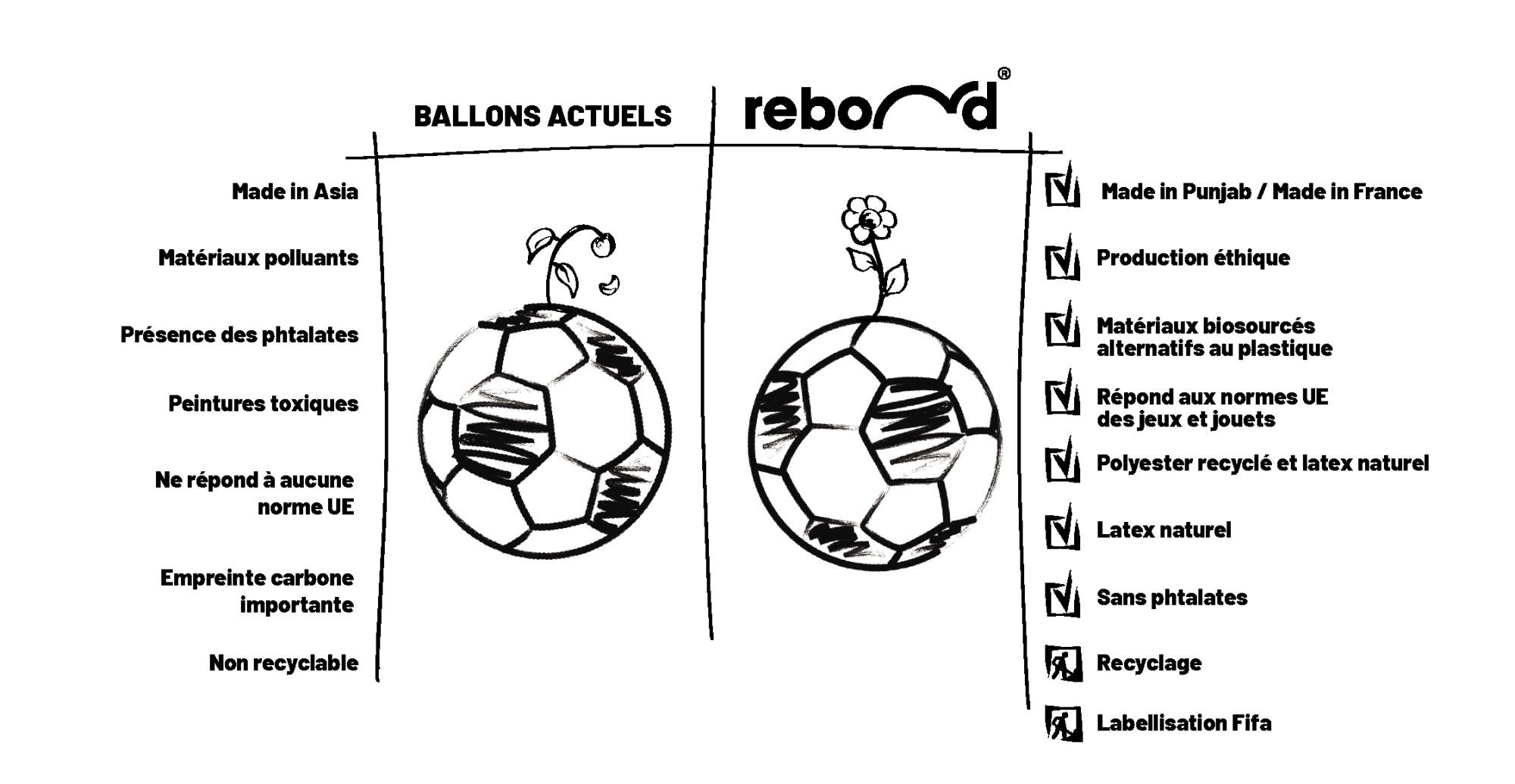

By reinventing the way sports balls are made, we've reduced the amount of fossil energy used in the ball, and worked with as many natural materials as possible. By making the ball single-material, we have made it recyclable. Accompanied by French industrialists who joined the adventure, we were finally able to bring out the first bio-sourced, recyclable ball to meet international competition standards, in 2022.

Inside the balloon, we use recycled polyester and a natural latex inner tube, in order to have the healthiest balloon possible.

Today, we're able to create balloons that are as clean as possible, containing no phthalates, and whose inks comply with strict European toy standards (EN71).

We continue to work on reducing the impact of ball production on our environment, and aim to offer a premium Technical range, labelled and logoed by international bodies such as FIFA for soccer, to provide our balls to sports clubs.

The nowadays balls production : Did you know ?

Have you heard about imitation leather when talking about the football ? Behind this term is « simply » hidden plastic: all balls are now made of PVC or PU.

Nowadays when we are all moving towards a healthier world, and consumption committed to products that respect people and the environment, the ball acts as a bad student through the materials used and in its production methods.

Especially since no European standard governs the sports ball when entering our territory: a door open to many cases of abuse.

Behind our ambition, hides a real societal issue: that of influencing a positive impact by producing healthy materials, to respect people as users and producers, as well as our planet.

We have a strong desire to show that we can turn around an existing economy by basing it on an irremovable foundation of ecological and social values.

Made

in France

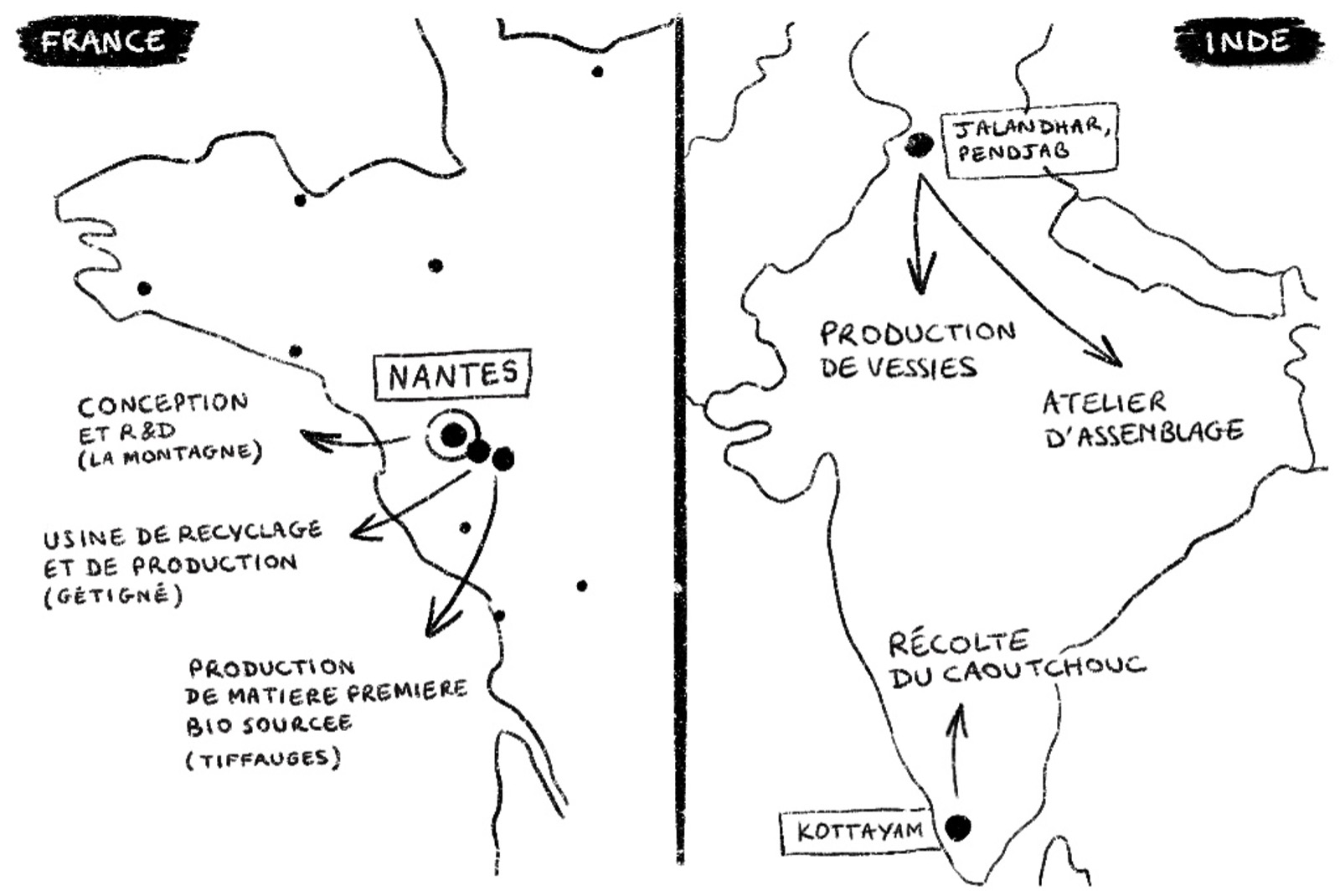

Working with Punjab, the historical cradle of the sports ball, and creating a production line in France: a great challenge!

Today, Punjab (the region straddling Pakistan and India) accounts for 85% of the world's manual production of sports balls. A cultural know-how that both countries have acquired through their history, and which is part of their heritage. The ball is to this region of the world what soap is to Marseilles, marble to Italy and cashmere to India.

Armed with knowledge of this history in Punjab, which saw the birth of a video report on the history of the balloon Our aim is not to relocate Punjabi know-how and develop the local economy. Our aim is to develop a French production chain to complement these workshops. In France, we are fortunate to have access to excellent engineering, enabling us to challenge the materials used on the ball. We see this French and Punjabi knowledge as complementary. In our view, eco-responsibility should be seen in an international rather than a national context.

Since 2019, we have developed a French production line whose assembly workshop is located in Loire-Atlantique (44).

French company

Secure payment

24h delivery with Chrono - 72h with Colissimo

Customer service