L'ÉQUIPE: Thanks to Rebond, the production of footballs is being relocated to France

L'Équipe puts us in the spotlight through the lens of the re-introduction of sports ball production in France.

Enjoy the reading!

We're going to tell you about a time that people under 40 can't know. Argentina at that time was hosting the World Cup. And the Tango, the official ball of the competition in 1978 (Adidas brand), was made in a workshop in France. A bygone era. The balls now come from the other side of the world, mainly from Punjab, a region located between Pakistan and India, but also from China.

And what about France? It could return to the centre of the game. Because the ball "made in France " will develop in the next few months, thanks to two companies, Rebond and Ballons & Co.

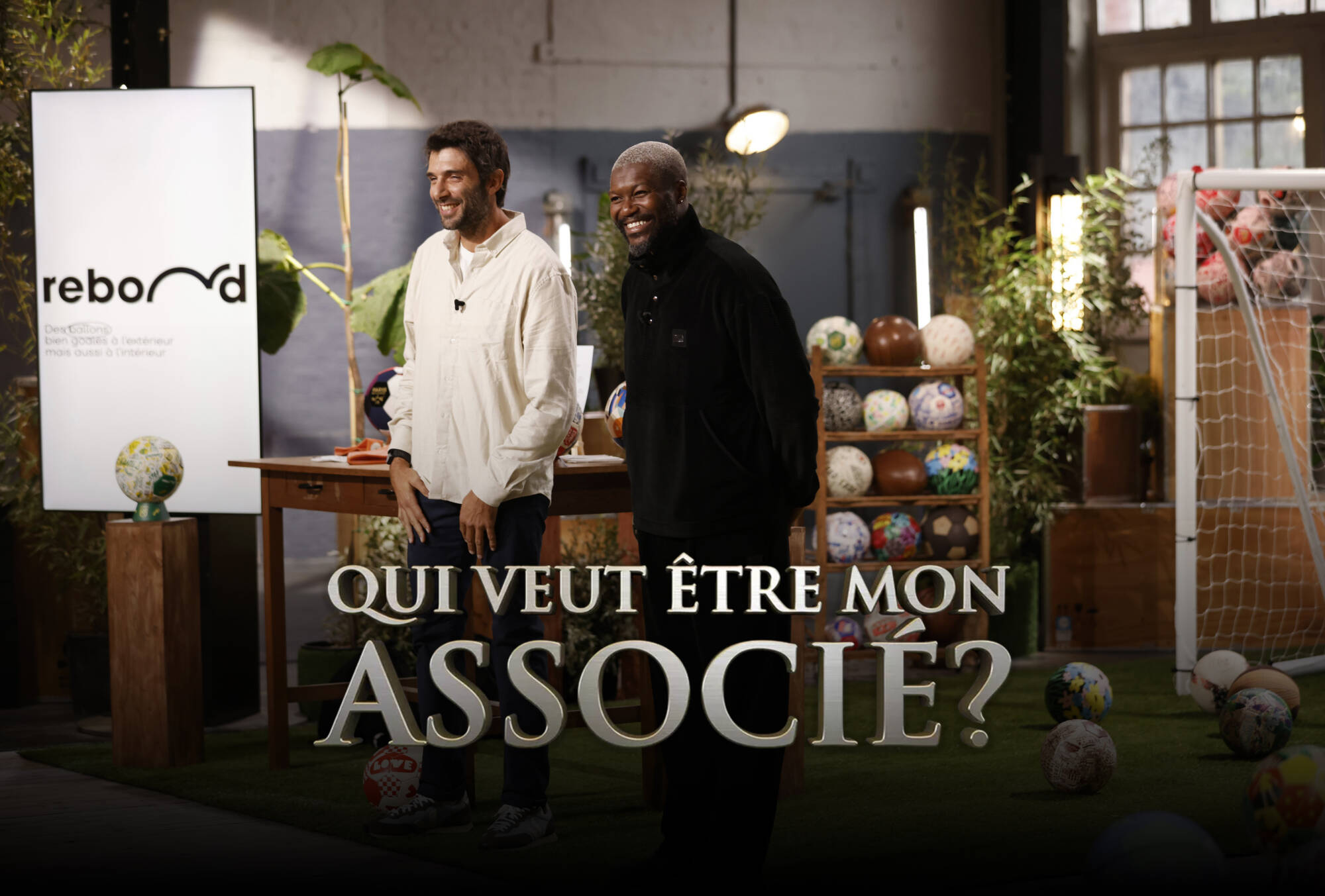

Rebond is the most advanced: it manufactured its first balls in France this year, through a collaboration with PSG. Fifty original balls, made in Gétigné, Loire-Atlantique, thanks to the recovery of historical shirts of the club, were sold in limited edition for the fifty years of Paris-Saint-Germain.

We wanted to produce more locally," explains Simon Mutschler, the company's founder. We had been working for three years and we managed to set up a 100% French production line. The assembly workshop is in Loire-Atlantique, the materials used come from the Ain region and the industrial partners are located in Loire-Atlantique and in the North. " It is not intended to be a 100% replacement for our current production line in Punjab, but rather to complement it," adds the thirty-year-old.

Because Rebond used to manufacture all its balls in this region of the world until now, and in particular the fruit of its collaboration with FC Nantes, a ball sold for 45 euros each at 1,200 copies in two months in 2019. When you say Punjab, you immediately think of child labour and cheap labour, but there is now a real social framework for work and workers," says Mutschler. Our ball is Fairtrade labelled, an international fair trade label managed by the NGO Max Havelaar, which audits and helps factories to respect decent labour, social and environmental standards."

From the Loire-Atlantique, we go to Marseille, where Jean-Baptiste de Tourris (Ballons & Co.) has decided to embark on the same adventure. His balloons will be assembled in Marseille, in the northern districts. My driving force is professional integration," he explains. I am currently working with young people who are far from employment and I want to help them find work. The young man therefore wants to recruit people on the RSA, on long-term unemployment, or without qualifications. And they won't be working on just anything, but on a balloon made of 90% recycled materials.

"We work with a partner in Kenya who recovers leather from plane and car seats and transforms them into octagons. We are also going to reuse the bladder of used balls. We are starting to recover a lot of them, clubs and individuals are sending us some. The whole thing will then be made up. We didn't want to work with eco-materials," explains the entrepreneur. We are convinced that we can use waste materials to make balls that comply with FIFA performance standards.

That is to say, match-quality balls, with which you can play football. Like the Rebond ball. The founder of the company has many projects and hopes to offer a " ball made of bio-sourced material, i.e. the residue of organic materials, such as corn husks or hemp. We're going to use food scraps to make a material.

French company

Secure payment

24h delivery with Chrono - 72h with Colissimo

Customer service