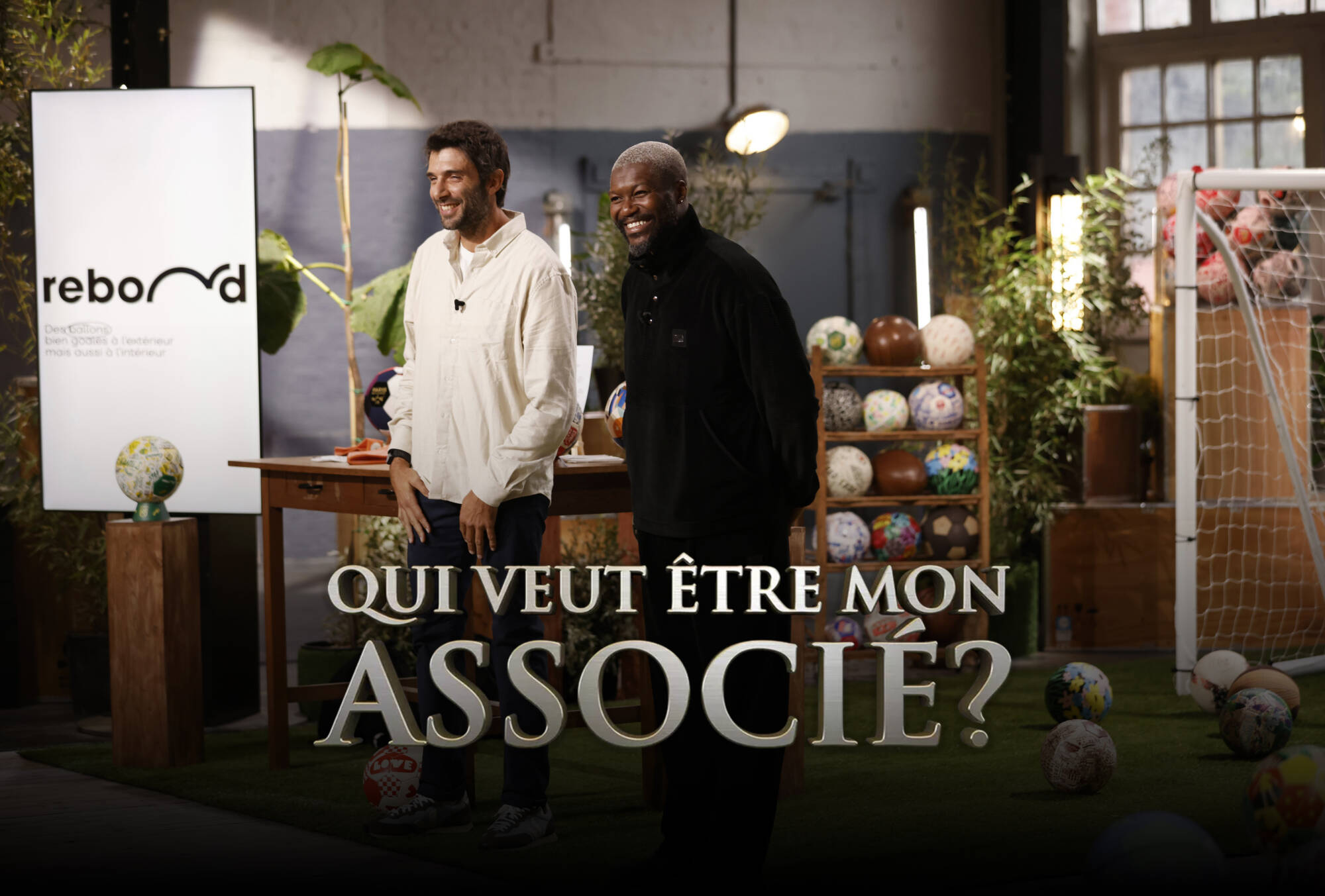

CAVIAR : Rebond, the start-up that takes the leap

Through his article in Slate, Louis Fabre draws a parallel between Rebond’s ambition to make the ball healthy and the current functioning of the "footosphere". A rise which calls the Federations to Rebond.

Enjoy the reading!

An eco-responsible ball ? It's possible. Recently, Simon Mutschler, 34, and Louis Guillizzoni, 35, have kicked off the very particular anthill of the production of these indispensable little spheres.

Presentation.

"Balls that are well scored on the outside but also on the inside." The phrase found on the brand's website is as smiling as it sounds good, to be sure. Communication is good at Rebond. But for the young Nantes start-up, fine words never remain in vain. Simon Mutschler and Louis Guillizzoni, founders of the SG Ball company, have been supplying football players with spherical leathers for almost ten years. In the time spent discovering this special market, the two young entrepreneurs got to know it more in-depth and quickly realized that in this world, everything is still not going very well. “You should know that 95% of sports balls used by professional clubs are imported. They are produced in the province of Punjab, at the borders of India and Pakistan, because the region is endowed with real historical know-how inherited from the colonial period, ”said Simon Mutschler. So, for these Nantes ex-students in business and journalism school, it appeared necessary to get involved in making things happen in a social and ecological logic in order to make the ball, a real eco-responsible product, locally manufactured and original.

The good, the beautiful, the true

For this, it was first necessary to familiarize yourself with European law and more particularly its restrictive standards concerning games and toys. Exit therefore phthalates, these toxic plasticizers, and other inks harmful to health. Giving a legal framework to the ball was the essential condition for launching the project. Then, a whole reflection on the materials used was carried out. Always intending to manufacture a healthy product, the young entrepreneurs, therefore, paid special attention to the selection of a raw material, which is obviously recycled. Plastic waste is collected and then crushed into granules before being transformed into PVC sheets whose flexibility allows the balls to form.

In order to always master this very special production, Rebond has made a bet that sounds obvious: made in France. Simon Mutschler explains: “We have chosen to produce our balls in our Nantes region. Paprec, a recycling plant already involved in the world of sports, supplies us with the recycled base material and local factories take care of the final upcycling, namely the transformation of PVC sheets into real sports balls. "But the case is not yet in the bag ! What would a particularly polished interior be without a neat exterior ? This is why the Rebond ball is the subject of an artistic work that makes it so original. The brand partners with local artists who have free hand to design the sphere. Judge for yourself the result.

First ball created by the brand released in September 2019 in collaboration with ... FC Nantes, obviously.

Good, beautiful but also true. Because beyond its particular characteristics, the ball from Rebond meets FIFA standards, allowing it to retain its essential function as a necessary instrument for a football match.

A rebound that is going to last

- What about the results? 500 balls sold in ten days for the first ball resulting from the collaboration with FC Nantes, and a decent start for the second. a brand that caught the eye of the biggest European clubs such as Bayern Munich, Liverpool or Manchester United. If the lockdown brought production to a halt, the brand quickly rebounded (no wonder). Difficulty transformed into opportunity and Rebond teamed up with the Fondation des Hôpitaux de Paris to create a balloon, the proceeds of which were entirely donated to the foundation. Very nice.

- While each new creation is in a limited series, it is continuously that new projects are in the minds of the two Nantes residents. The next collaborations in the fall as well as in the spring. According to them, it is essential to act now : «We are determined to make sport the vehicle of new environmental values. In France, there are still too few precursors. However, the balloon can say a lot of things about the society in which we live. Like football, it is everywhere, popular and unifying. By acting on its market, we want it to take the essential ecological turn. »

The ball, as basic as it is, nevertheless says a lot about the functioning of the football planet. A metaphor for the financialization of this sport, its production has been the subject of almost exclusive control by certain transnational firms for years, which then sign exclusive equipment contracts with international federations. Wouldn't it be time to think about Rebond ?

French company

Secure payment

24h delivery with Chrono - 72h with Colissimo

Customer service - 06 75 42 83 78